Businesses thrive by growth. Leaders are expected to find innovative ways to propel the organization in the new direction and to make that growth vision a reality. In this game, most of us take for granted, the fact that the processes we own need our attention. I’m not joking. Smart managers are compelled to delegate the monitoring or upkeep of the processes to their smartest subordinates; And conveniently focus their own energy on transforming the business.

Unfortunately Murphy plays havoc, all the time. In reality, time goes in fire fighting, leaving none or very little for change or transformation effort. In fact, the more you plan to devote time for transformation, the more you plough your head into daily issues. The time that you devote to unplanned daily issues can be equated to a cache, such as the one in your computer, except that this one is a ‘Management Cache’.

It stitches together a set of simple tools and techniques to put the concept into action. It takes an integrated approach. In fact, the lack of an integrated approach to daily work management is often recognized as the root cause of fire-fighting, because even a manager who is diligent, soon or later swirls into fire fighting.

Nichijo Kanri integrates role definition as defined by HR, process specification and standards as defined by process experts, individual potential and collaboration efforts. It uses tools such as Managing Points, Checking Points (MPCP), check sheets, visual management methods, gemba walks, huddles, accountability circles, kaizen, etc

Whether you are small business owner or a senior management professional in a mature corporate set-up, Daily Work Management System can revive & restart your system that clears the management cache and gives you peace of mind. It is fuel you to scale up your organization and, in fact, even fuel your own growth prospects.

If you wish to implement Daily Work Management System in your organization, pls feel free to contact us.

In a continuous improvement journey, improvement projects are nothing but the lifeline. In this series of articles, we covered on the Need for Project Selection and the Criteria for project. Now we’ll answer the big question – Where can I get my projects from? Essentially various sources of the project!

If your organization has a list of customer complaints, then that is an apt place to commence. Complaints are not only sore for your customers, but for you too. Such complaints may cover a vast product or service attributes such as product or service quality, delivery time, responsiveness, people issues, pricing or areas of monetary impact including warranty claims, process & policy issues.

You can go one step further and target repeat complaints instead. Repetitive complaints from the same customer with the same tagging indicates high priority area for improvement.

Few organizations target the need of customers to call or contact organization and, reduce them. It might not be a complaint, instead just an enquiry or request. In other words, interactions with the organization that can be avoided. Looking at enquiries and requests serve as a proactive means to identify future problem areas.

If your organization conducts structured VoC surveys, then the outputs of such mechanism can be a good source of Continuous Improvement or Lean Six Sigma projects

Customer Experience is usually hidden and not so obvious as customer feedback. Structured and unstructured mechanisms can be deployed to understand the customer experience. For example, many organizations now use mystery shopping to unearth issues in customer experience. Observation or Listening posts are also a good way to identify how customer experience can be improved.

If you closely have a look at your company’s process, you will find that there are many internal defects (work-in-progress) occurring, such as rework, repairs & in-process rejections. Such defects are silent killers because they drain organization’s efficiency and effectiveness silently. If your organization is measuring FTR, then its improvement can be an ideal project. More evolved organizations use RTY (Rolled Throughput Yield) as a metric which is also a good place to demonstrate Continuous Improvement.

However, most organizations have a simpler measure of success for quality – Defect Rate (% Defective). While there’s nothing wrong with this metric, is a bit holistic and hence factors leading to inefficiencies escape unnoticed with this metric. Nonetheless, it is good starting point for Continuous Improvement projects.

Field failures are sometimes grave. It can cost you a lot and, the overall cost of ownership for customers might increase esp if the warranty is denied or the product is under breakdown. In broader terms, the principle of warranty is to institute accountability in the event of an untimely failure of an item or the inability of the item to perform its intended function. Experts consider reliability data analysis as a quality measure over time. This reliability analysis is done to analyze whether your product will survive for the time defined by the company in the normal conditions. Improving the reliability of a product can work both ways – organizations can lower its operational cost and provide longer warranty and customers would experience break down less often.

If your organization has a well-defined and structured reporting mechanism for process performance metrics, such as a dashboard or scorecard, then it would be a very good source to identify opportunities for continuous improvement projects. As leadership teams are consumers of such reports, such opportunities can easily gain sponsorship as well.

Benchmarking is a continuous process of comparing your firm’s or company’s practice to those of the competitors or say most successful competitors. In certain cases, you might not be doing well. For example, having control over the delivery time to the customers. Then this can be taken as a project for improvement in our company. So, to generalize, competitive benchmarking results can also be a good source for Continuous Improvement projects.

Gap between strategic plan and reality can be the cause of concern for leadership. Sometimes such problems may be because of supporting processes. They can hinder new business plans or strategies. Such process improvement opportunities are also a good source for projects, provided they are scoped well with well-defined objectives & goals.

While customers don’t see your process but only experience its outcomes, employees have an end to end visibility. They experience problems as customers and can associate inward aspects of such poor experience. Many organizations, pilot their products with employees, because employees are pseudo customers. If you can establish a structured process through which employees are encouraged to share their experience and enable them to take up such opportunities as Continuous Improvement or Lean Six Sigma projects, there’s nothing like it.

All the above can serve as a good source for Continuous Improvement or Lean Six Sigma projects.

from Canopus Business Management Group

We talked about the need for Lean Six Sigma project selection in detail in the earlier articles, in this one we’ll cover the criteria for selection and the in the following article, we’ll move on to talk about the tools used for selection and how to engage the stakeholders in the process.

I have found that while leaders agree on the need for project selection, their views on the criteria is quite divergent. Most of them see this as a process to sway the process in favor of their priorities and interests.

There is nothing wrong in doing so, as long as the process is not biased.

Through this article, we draw consensus on the criteria and its relevance to the whole process.

The real good news is that the criteria for getting the project selection right are not too complicated.

What does project selection countdown look it? We’re going to start with the least of the top 5 criteria and find our way to the top most criteria.

Here you go:

7. Probability of Success:

Not all the projects will be successful in any company. Hence, while selecting the project, most project leaders consider the contingencies which might come up and use that as a yardstick to select the project. Sponsors want their project leaders to be successful equally as projects leaders’ desire success. Well, sounds like a good approach. But doesn’t this approach make it very orthodox? Unlike other implementation projects in technology, improvement projects are bound to have ups and downs; and it is quite natural that not all projects achieve their goals. That is what continuous improvement is all about.

Thus choosing to play it safe isn’t the best criteria to select projects, though unfortunately, it is very popular criteria in use. That is why Probability of Success is the last in our countdown list! One of the organizations flips these criteria to select the project which has failed in the past or have a low probability of success as Black Belt project. That is certainly a best practice to emulate.

6. Availability of Data:

Is data readily available for the project? If not, can it be easily gathered? While most project leaders and sponsors know that rarely will all the data needed for a project is waiting around to be analyzed. But they use the availability of data criteria to select projects because the unreasonable expenditure of time, resources and effort can be avoided. Yes, data is needed for analysis. But making it a criterion reduces the scope Continuous Improvement deployment.

Improvement projects are expected to venture into unchartered territories of the process and present root cause and opportunities. Getting people to measure something that is not being reported till now, in it is a feat. Having vanilla project can hardly be a criterion for project selection. That is why the availability of data comes second last in our countdown!

5. Savings potential:

Any project implemented is implemented with an intention to gain any kind of tangible or say monetary benefits. But along with monetary benefits, there are other benefits like customer satisfaction, increased efficiency, total company involvement; increases workspace and much more. While it is absolutely apt to select projects which have savings to the organization, it is misleading to make saving potential a primal purpose of projects. I have seen many times, project leaders come up with simple ideas or improvements with a huge saving potential to the organization, but virtually no complexity involved. Such projects hardly qualify for Black Belt projects.

They best serve as Just Do It project. Giving undue importance to saving potential in project selection also sends the wrong message across the organization. That is why I not really excited about having this as a top item in the countdown. That’s why Saving Potential is only Number 5 in our countdown.

4. Apt Time:

There is always a perfect timing to initiate a project. Relevance is contextual. By apt timing, I mean both the time to commence, and the closure as per plan. An important project has to close on time. It has to be first of all, planned to close on time. It has to be scoped to close on time. That is why Apt Time is No.4 in our countdown.

3. Availability of Resources:

I don’t know if this has to do with the culture. Most organizations, if not all, end up with a laundry list of projects because everything seems to be Business or Customer priority. Even the biggest and richest of the organizations have limited resources. Either resource is depleted, busy elsewhere or simply not committed to deliver. The best person is often leading many projects, making everything he/she does venerable to failure. Project selection is about de-selection and not selected. Ruthlessly put ideas into a parking list for which right resources are not available; and if it is so important that it has to be executed now, then pull the right resource into this project rather than sharing.

While I have largely kept this point around manpower, it equally applies to money & time. I say with conviction that organizations that ensure that the leader of the Lean Six Sigma project is a dedicated resource, either full time or handling only one project even if it means he is part time on it are surely successful. This is why Availability of Resource is No.3 on our countdown!

2.Customer impact:

Ask yourself “will the results of the project bring any difference in the life of the customer? Will it improve the perception of the customers about the quality of your product or services?” Quite often this answer to this question is yes. Unfortunately, it’s motherhood in apple pie question. So insist on quantifying the impact.

If you can pin a number to the impact, then go ahead. And if you’re not able to do so, then there’s no point in wasting your time on the project. Consider Voice of the Customer in your organization as a starting point. Why don’t you start with complaints and alleviate customer pain? Thus Customer Impact is Number 2 in the countdown.

1.Business Priority:

Selection of projects is based on the need or priority of the business. Project leaders need to understand that the tail can’t wag the dog. Often, people package their ideas into a project and fuel it as an organizational priority. Scanning of the external and internal environment will give first-hand insight on what is the organizational priority, NOW? Go for it. Well, that may put you out of your comfort zone, competency or expertise, but remember that’s what the organization needs.

Without a real need, do you think any leader would offer sponsorship to your project or will it at all help anyone – NO.? That is why Business Priority is Number 1 in our countdown.

Project Selection and implementation of Lean Six Sigma is easy and at the same time should be handled delicately by keeping all the above aspects in mind otherwise it might turn into a big disaster. An effective diagnostic study is required before selecting projects and with the undivided involvement of the top management are pre-requisites for project selection.

Why should you be worried about Project selection in any Continuous Improvement (CI) Program?

While leaders strive to build a culture of continuous improvement (CI) in their organizations, it is equally important to understand that business-as-usual activities take precedence over improvement activities. CI programs commence with a big bang and a lot of enthusiasm, but time wears out even the strongest and what it leaves behind is mere CI hubbub. This is not a simple problem to solve. If you have been part of any enterprise-wide CI deployment, you will have no difficulty relating to this. This problem is complex and has several failure modes.

In this article, I’ll like to highlight a common but significant failure mode – Selection of projects. It’s needless to emphasize that projects play a big role in any CI journey, but to its disgrace, projects are also a significant contributor to the downfall of CI program.

Going overboard and having too many concurrent projects is one way to fail. Not selecting the right projects to pursue is another. Here are few compiling reasons to consider project selection as an important activity rather than opening the floodgates of projects:

Business Priority:

Every business has its own priorities and so it’s important to select the right projects that are aligned with your priorities. Having many dispersed projects will blemish, if not nullify the impact of projects. Alignment between leader’s priority & CI program can be easily accomplished if you select projects right at the beginning.

Change due to competition:

If your competition is disrupting the industry, well you better select where you need to improve. External environment often forces organizations ruthlessly reform their way of thinking and working. And today, we all live in a world that is fast changing. So unless your right projects are selected and pursued, your CI program will become redundant soon.

High Customer Expectations:

Everyone I talk to says, customers are demanding more than ever before. Understanding the changing their needs and aligning the CI program to customers is vital to the success of any organization’s CI program. Organizations sometimes pursue trivial opportunities such as cost saves but miss on acting on big ticket customer facing projects or customer pain points. Of course, while dealing with customers, things are going to be volatile, but that’s not a reason to avoid them. The good project selection process should filter such project opportunities.

Limited Budgets:

All organizations must work within the framework of budgets. Improvements need monetary resources to support the change. Sometimes they are direct and hence easily associated to direct cost centers. But projects with intangible benefits or the ones incurring indirect costs usually end up as scapegoats. If an organization commits to project selection, many such failures can be prevented.

Availability of Resources:

Human capital is scarce. CI projects need quality time and mindshare from people of importance in the organization. Quite often resource requirements are never considered during the commencement of projects. Even if considered, it’s only the project leader’s time. As CI projects are a cross-functional effort, active participation of experts from all involved functions defines the success of the project. In order to ensure we get the best out of our teams, we need to time our success. Thus project selection is a time sensitive activity.

Optimizing Number of Projects:

Not all the areas of your organization need improvement at the same time, And improvement culture building is a slow and steady process which can never be implemented overnight, nor will the results reap overnight. So getting to rush out the organizational adrenaline may not be a success recipe for good CI program. Selection of projects will ensure that you sustain optimum enthusiasm in the system for CI.

So it is very evident that selection of projects impacts the CI culture, employee satisfaction, alignment to customers and ROI to business for the investments it makes in CI in a positive way. In the future articles, we’ll take this one step further and talk about the criteria used for selecting projects.

As an entrepreneur or subject matter expert, building an product or service isn’t really difficult because you have all the ideas are packed in your head. In fact that is true for any one skilled professional. Unfortunately that doesn’t guarantee success when it comes launching a successful product or service.

Customers will choose or recommend products that best address their needs. Here’s an interesting real life story of a Jewish immigrant couple trying to meet their ends. In this process they end up building a business empire. I read this story in the book ‘Outliers: The Story of Success’ by Malcolm Gladwell.

Louis and Regina Borgenicht landed in America in the year 1889 as immigrants. Louis was struggling to feed his family of four. He tried various odd jobs with little or no success. He was desperate and was about to quit.

Here’s an extract from the book:

“The answer came to him after five long days of walking

up and down the streets of the Lower East Side, just as

he was about to give up hope. He was sitting on an overturned

box, eating a late lunch of the sandwiches Regina

had made for him. It was clothes. Everywhere around

him stores were opening—suits, dresses, overalls, shirts,

skirts, blouses, trousers, all made and ready to be worn.

Borgenicht took out a small notebook. Everywhere he

went, he wrote down what people were wearing and what

was for sale—mens wear, women’s wear, children’s wear. He

wanted to find a “novel” item, something that people would

wear that was not being sold in the stores. For four more

days he walked the streets. On the evening of the final day

as he walked toward home, he saw a half dozen girls playing

hopscotch. One of the girls was wearing a tiny embroidered

apron over her dress, cut low in the front with a tie in the

back, and it struck him, suddenly, that in his previous days

of relentlessly inventorying the clothing shops of the Lower

East Side, he had never seen one of those aprons for sale.”

Rest of it is rags-to-riches story. The couple built a thriving business and a niche for women and kids apparels.

This lesson of success hasn’t changed with time. If you want to be the Borgenicht of your business line, then let the designing your new product start with what we define as ‘Gemba’. It is a Japanese word implying ‘the real place’. Borgenicht painstakingly yet meticulously gathered insights from Gemba. For your products or service, ‘the real place’ is where it is been used by your consumers. Hence ‘Gemba’ is the fountainhead of your new product ideas and implementation roadmap. Market Research is supposed to do that, but in today’s world, it is outsourced to an agency. Market research reports contain only tangible factors but Gemba insights are missed or misunderstood.

If you have a new product or service development lined up, it would be in your own interest that you visit ‘Gemba’ and gather insights that will feed to the success of your product rather than review the new product development plan in the board room sipping green tea and munching cookies.

Consider a Gemba visit for the following:

- Deciding your target segment

- Who will buy our products and who will not?

- Understanding common needs of different customer groups

- Understanding articulated and unarticulated customer needs

- Understanding customer journeys

- Understanding substitutes and alternates for your product

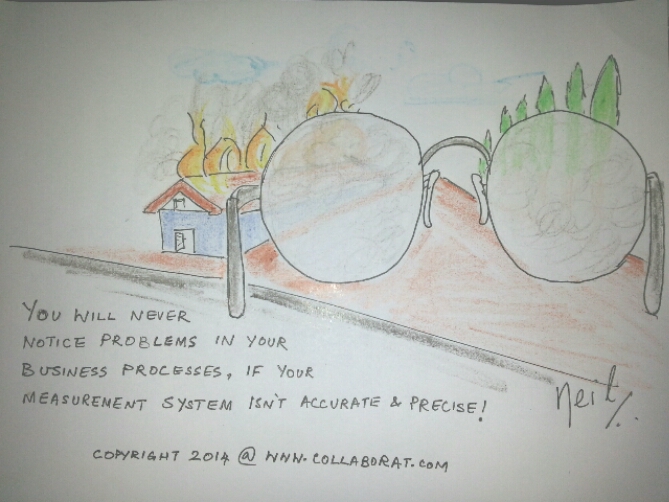

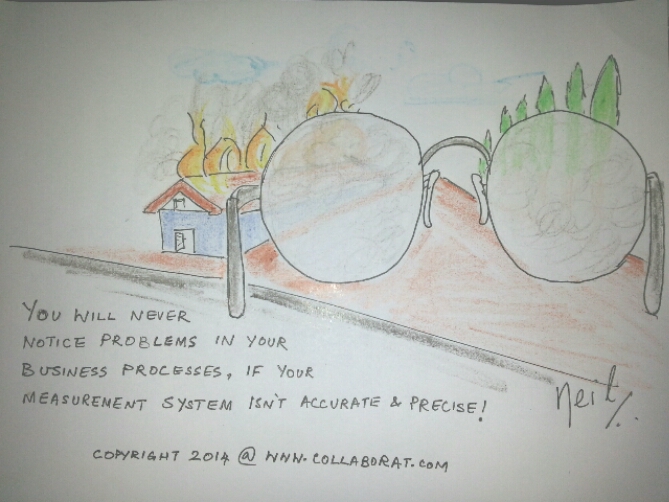

You will never notice problems in your business processes, if your measurement system isn’t accurate & precise.

Indeed they are different; Most widely accepted definition of a consultant is an expert or a professional in a specific field and has a wide knowledge of the subject matter and one who provides advice in that field.

So by definition a consultant has very limited execution responsibility. However commercialization of the ‘Consulting Industry’ and intense competition has led to a situation where firms promise to own or share responsibility of execution. But in reality, they primarily role is to advise so things fall through the cracks as the engagement proceeds.

Due to their envious position as subject matter experts, consultants usually have an upper hand in their relationship with clients. Many times, this biased relationship is not very conducive for building trust and confidence between both the parties.

“The test of a good consultant is not whether he or she has generated a unique insight, but whether the insight can be applied to produce positive results. Consultants can’t just be smart; they have to be capable of delivering a business outcome” – The Economist

That is why consultants are usually criticized for the following:

- Theorizing problems and making them difficult to comprehend

- Heavy usage of Jargon!

- Force problems into a ‘methodology’ they know

- Attempt to make projects bigger or longer than they need to be

- Produce an elaborate dossier called ‘Project Report’ that reiterates the problem

Not all consultants have such deficiencies, but it is very prevalent.

‘Collaboration’ on the other hand is a recursive process where two or more people or organizations work together intersection of common goals – for example, an intellectual endeavor that is creative in nature -by sharing knowledge, learning and building consensus. Collaboration does not require directive leadership and can sometimes bring better results through decentralization and egalitarianism.

Traditionally, collaboration is widely popular among authors, academicians & researchers. These are fields where two or more experts with diverse and varied experience work together to towards a common goal. So ‘execution & result orientation’ is at the heart of collaboration. And unlike consulting, there is no role to just ‘advise’ and not own execution.

Good collaboration has the following elements:

- Tactical – Where one tells other teams members specifically what to do in his/her areas of expertise

- Tacit – Where one trains other members on how to handle issues/situations beyond technical stuff

- Co-delivery – Where one dirties his/her hands and work together with the team

- Partnership – Where one recognizes that they are not experts in all disciplines. Hence he/she partners with other experts in the team

There is no need to emphasis which one is better when it comes to ‘change management’. Collaborative style of change management is several notches above consultative style.

Known in short as Neil, Nilakantasrinivasan helps individuals and organizations to improve their performance, profitability and processes.

He is an expert in Operations Management, Customer Experience & Project Management.

Neil’s approach is not to prescribe any ‘methodology’. Instead he uses his experience with Hoshin Kanri, Balance Scorecard, LEAN, TQM, Six Sigma, Triz, Theory of Constraints, Knowledge Management, industrial engineering methods, ISO, PCMM, etc to deliver a composite solution that will resolve the pain points and improve profitability, productivity & process.

How Six Sigma Black Belts Can Deliver Choku-Zuki* as Internal Consultants?

*Choku-Zuki in Karate refers to straight punch

General Electric, one of the largest producers and suppliers of Lean Six Sigma talent by the turn of last century is no more an ardent advocate of this principle. GE isn’t alone; there are many other enterprises like Bank of America, Citibank which have moved on. While the demand for Six Sigma Black Belts has been steadily declining in some economies, most ticking economies have mentionable demand. Several third party certification agencies have replaced GE and other large corporations as the suppliers of Lean Six Sigma Black Belts.

Where do all these changes leave a Certified Lean Six Sigma Black Belt? Black Belts have been under tremendous pressure to cope with dynamic needs of business leaders they support. Traditionally, external consultants from Big 4 and the next rung of firms were hired for delivering Quality and Productivity enhancement projects. Today, Black Belts hired on company rolls are managing these projects. So they are well positioned and duly expected to act as ‘Internal Business Consultants’.

Like a half filled glass, this is certainly an opportunity and threat. But the odds against Black Belts are so high that this glass isn’t half full but nearly empty one!

The inconvenient truth is that most Certified Lean Six Sigma Black Belts stand no competition to Operations Management Consultants from the Big 4 or firms.

The gap really isn’t about the body of knowledge (bok) or the versatility of playing with Minitab or JMP screens. It goes beyond this and requires closer examination.

While hiring an external consultant, clients look for referrals, credentials, chemistry and demeanor. A good consultant is someone, clients hate to see go when the project ends on time and is preferred choice of re-hire for the next suitable assignment.

Many black belts wouldn’t openly agree but concur in confidence that business leaders see them as ‘imposed bodies of cost’ that should be off-loaded sooner or later. As a matter of fact, Black Belt’s presence or absence hardly makes any difference to them.

I wouldn’t hold Black Belts solely responsible for this situation. CEO’s intent, Six Sigma deployment leader’s effectiveness, organizational culture and many other factors play havoc. But for now, I would like to restrict to things which are well within the control of Black Belts. After all a Black Belt is the biggest stakeholder in her own career. Let’s examine the barriers(don’ts) and levers(dos) for Black Belts to become a preferred choice of consultant (both internal and external).